In the “Configuration” tab, the individual network components are configured based on the entries defined in the “Components” tab.

In detail, it concerns the following:

- the equipment at demand points and POP

- the fiber configuration at demand points

- and duct-type mapping.

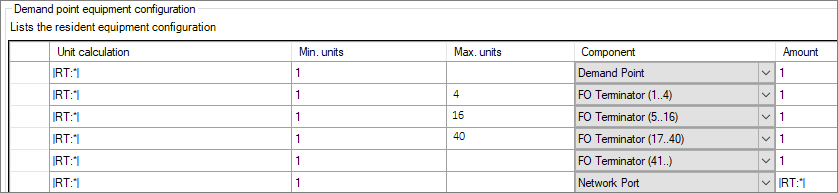

Demand point equipment configuration

Which components are to be planned in the demand point is defined at this point.

A formula is used to calculate the units. Explanation by the example |RT:*|

- | is the vertical line (pipe) on the >< key and opens the instruction

- RT stands for resident type

- : after the colon

- * represents the sum of all demand units

- | closes the instruction

Instead of the placeholder *, the demand units—LU, BU, etc.—can also be accessed directly.

The application of the formula can be restricted under “Min. units / Max. units”.

The entries defined in the “Components” tab are shown in a drop-down menu under “Components”.

The fiber requirement is defined under “number”. A fixed value or a formula can be used here.

Interpretative examples

- Line 1 > If the sum of all requirements (LU, BU, UT3, UT4, UT5) is at least 1, plan exactly one drop. In other words, even where there are more than one residential and business unit, etc., only one drop is planned per building.

- Line 2 > If the sum of all requirements is between 1 and 4, plan exactly 1 FO terminator (1–4).

- Line 5 > If the sum of all requirements is greater than 41, plan exactly 1 FO terminator (41–).

- Line 6 > Plan one network port for the sum of all requirements for each unit.

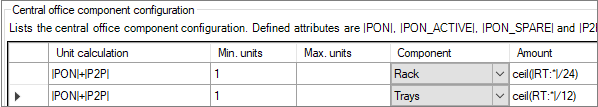

Central office component configuration

Defines the equipment for Central office locations. |PON|, |PON_ACTIVE|, |PON_SPARE| and |P2P|, |P2P_ACTIVE| and |P2P_SPARE| are defined, and these refer to the technologies of the building units.

Here, the units are calculated using the placeholders |PON|, |PON_ACTIVE|, |PON_SPARE| and |P2P|, |P2P_ACTIVE| and |P2P_SPARE|.

- The rule can be made more specific using “Min./max. units”.

- The “Components” are selected via a drop-down menu. The entries come from the “Components” tab.

Interpretative example

- In the example, the number of components is calculated from the sum of all requirements divided by 24 (one rack per 24 fibers) or 12 (one tray per 12 fibers). To ensure that only entire components are planned, the result is rounded up using the “ceil” instruction.

- In detail, the instruction is ceil(|RT:*|/24).

Feeder demand point component configuration

This is handled analogously to the demand-point equipment configuration.

Backbone demand point component configuration

This is handled analogously to the demand-point equipment configuration.

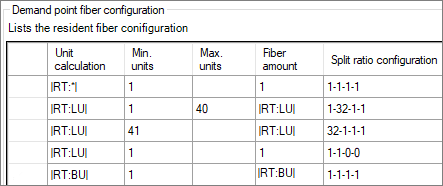

Demand point fiber configuration

This is where you define the fiber requirements of demand points based on the (building) units. The abbreviations for building units are defined under “Components”.

A formula is used to calculate the units. Explanation by the example |RT:*|

- | is the vertical line (pipe) on the >< key and opens the instruction

- RT stands for resident type

- : after the colon

- * represents the sum of all demand units

- | closes the instruction

Instead of the placeholder *, the demand units—LU, BU, etc.—can also be accessed directly.

The application of the formula can be restricted under “Min. units / Max. units”.

The number of fibers is again calculated via a formula or can be entered as a fixed value.

Configuration of the splitting factor

- The splitting factor must be configured for each network layer.

- Each entry represents a network layer: 1-32-1-1 = building-distribution point-POP-backbone point.

- If fibers are to end in a layer point, the subsequent splitting factors must be set to 0, for example: 1-1-0-0 > fiber is planned as far as the distribution point.

Interpretative examples

- Line 1 > For all buildings where the sum of all units is at least 1, plan exactly one P2P fiber from the demand point to the BB point. In this way, the building fiber can be depicted.

- Line 2 > For buildings where the number of living units is between 1 and 40, plan one fiber per living unit. A 1:32 splitter is used in the distribution point.

- Line 3 > For all buildings where the number of living units is greater than 41, plan one fiber per living unit. The splitter is positioned in the building.

- Line 4 > For all buildings that have at least one living unit, plan exactly one fiber that ends in the distribution point. Termination in the distribution point is achieved by the splitting factor configuration 1-1-0-0. This setting can be used for building spare fibers, which in our case are only drawn as far as the distribution point.

- Line 5 > For all buildings where the number of business units is at least 1, plan one P2P fiber per business unit from the demand point to the BB point.

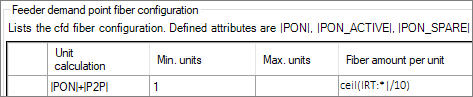

Feeder demand point fiber configuration

The fiber requirement of the POP is calculated taking into account the PON and P2P units, both active and spare.

It is handled analogously to the fiber configuration for a demand point.

Examples for configurations

The fiber requirement per unit can be defined by fixed values or calculated by formulas.

Fixed values, such as 12 define that each POP is connected to the backbone handover point with exactly 12 fibers.

More dynamically, the fiber requirement POP-backbone transfer point is determined via formulas. Examples:

|PON|+|P2P| -> the total fiber demand connection points-POP is planned 1 to 1 for the connection POP-backbone transfer point.

((|PON|+|P2P|)*0.001)+6 -> for every 1000 demand fibers at the POP, one fiber is planned towards the backbone handover point plus an additional 6 fibers

ceil(|RT:*|/10) -> Plan one fiber per 10 demand units and round up the result to a natural number

Feeder demand point fiber configuration

This is handled analogously to the demand-point fiber configuration.

Backbone demand point point fiber configuration

This is handled analogously to the demand-point fiber configuration.

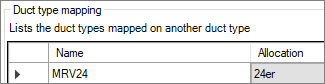

Duct allocation (or Duct type mapping)

This is where duct types that designate the same duct type can be summarized. The reason for this may be, for example, different notations for the otherwise structurally identical duct types.

- Name > Name of the duct type to which a duct type defined in the configuration is to be assigned

- Allocation > The duct types defined in the configuration are displayed here and can be assigned to the duct type to be replaced.